Top Small Compressor for Your Needs: A Complete Guide

By:Admin

{Company} is a leading provider of innovative and high-quality machinery for a wide range of industries, including manufacturing, construction, and automotive. With a strong commitment to excellence and customer satisfaction, {company} has established itself as a trusted name in the industry, delivering top-notch products and exceptional service.

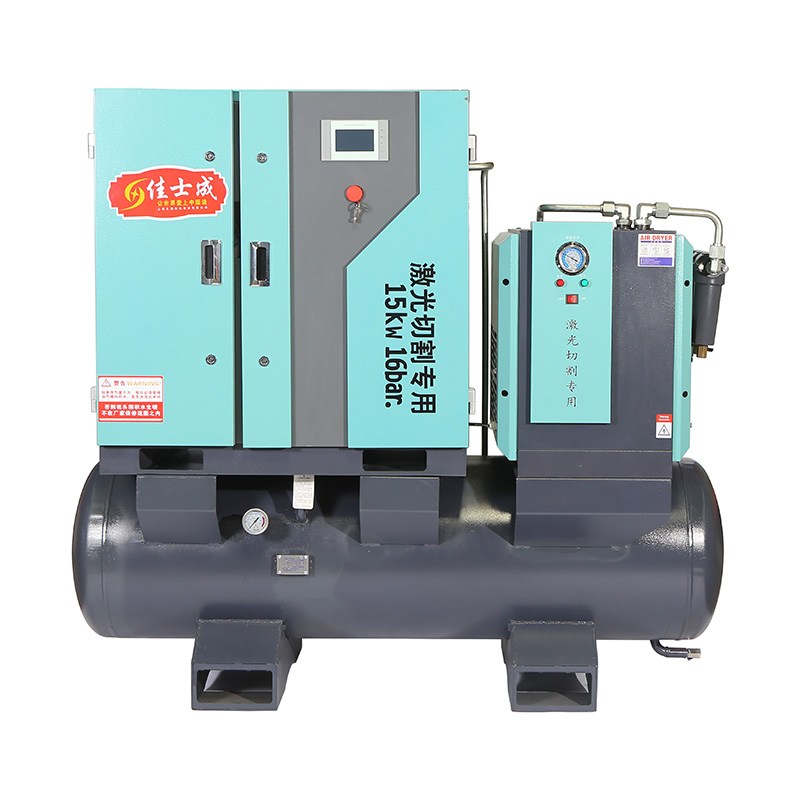

One of the standout products in {company}'s impressive lineup is the Small Compressor, a compact yet powerful machine that is designed to meet the needs of businesses of all sizes. Whether it's for powering pneumatic tools, providing clean and dry air for manufacturing processes, or maintaining pressure in a variety of applications, this compressor delivers reliable and consistent performance.

The Small Compressor is engineered to be versatile and user-friendly, making it an ideal choice for businesses looking for an efficient and cost-effective solution. Its compact size and lightweight design make it easy to transport and maneuver, while its durable construction ensures long-lasting performance even in the most demanding environments.

With a wide range of available models, {company} offers a Small Compressor to suit any application. From portable units for on-the-go usage to stationary models for continuous operation, customers can choose the right option that best fits their specific needs. Additionally, with customizable features and accessories, {company} can tailor the Small Compressor to meet the exact requirements of each customer.

Moreover, {company} takes pride in its commitment to sustainability and environmental responsibility. The Small Compressor is designed with energy-efficient technologies that minimize power consumption and reduce carbon footprint, helping businesses to operate in a more eco-friendly manner while also saving on energy costs.

In addition to its exceptional products, {company} also provides comprehensive support and service to ensure that customers get the most out of their investment. Its skilled technicians and service personnel are readily available to offer maintenance, repairs, and technical assistance, guaranteeing that the Small Compressor operates at peak efficiency at all times.

With its unwavering focus on quality, innovation, and customer satisfaction, {company} has earned the trust and loyalty of countless businesses across the globe. Its Small Compressor is just one example of how the company continues to deliver on its promise of excellence, empowering industries to achieve new levels of productivity and efficiency.

As industries evolve and the demand for efficient machinery continues to grow, {company} remains at the forefront, leading the way with cutting-edge solutions that empower businesses to thrive and succeed. With the Small Compressor, businesses can rely on {company} to provide the reliable performance and support they need to stay ahead in an ever-changing market.

In conclusion, the Small Compressor from {company} is a game-changer for businesses in need of a compact, reliable, and efficient solution for their pneumatic and air compression needs. With its exceptional performance, versatility, and commitment to customer satisfaction, this compressor is a testament to {company}'s dedication to excellence and innovation in the industry. Whether it's for small-scale operations or large industrial facilities, the Small Compressor is a testament to {company}'s dedication to excellence and innovation in the industry.

Company News & Blog

Learn the Basics of MIG Welding: Tips and Techniques for Beginners

Basic Mig Welding TechniquesWelding is a crucial skill in a variety of industries, including construction, manufacturing, and automotive. Among the different types of welding techniques, MIG (Metal Inert Gas) welding is one of the most popular and commonly used methods. MIG welding is known for its versatility, speed, and ease of use, making it a top choice for both beginners and experienced welders. In this article, we will explore the basics of MIG welding and how it is used in different applications.MIG welding, also known as GMAW (Gas Metal Arc Welding), uses a wire electrode that is continuously fed through a welding gun. The electrode is consumed as it melts to create the weld joint. A shielding gas, typically a mixture of argon and carbon dioxide, is used to protect the molten weld pool from atmospheric contamination. This results in a clean and strong weld, making MIG welding suitable for a wide range of materials, including steel, aluminum, and stainless steel.{Company Name} is a leading supplier of welding equipment and supplies, including MIG welding machines, consumables, and safety gear. With a strong emphasis on quality and innovation, {Company Name} is committed to providing the best-in-class products to meet the needs of welders in various industries. Their extensive range of MIG welding equipment caters to both professionals and hobbyists, ensuring that every customer can find the right tools for their welding projects.When it comes to basic MIG welding techniques, there are several key factors to consider. One of the most important aspects is choosing the right welding machine and proper settings for the specific material being welded. {Company Name} offers a range of MIG welding machines with different power outputs and features to accommodate various welding applications. Additionally, their team of experts is available to provide guidance on selecting the right machine and setting it up for optimal performance.Another essential aspect of MIG welding is ensuring proper weld preparation and joint fit-up. The metal pieces being joined must be clean and free of any contaminants, and the joint fit-up should be tight to ensure good fusion. {Company Name} offers a wide range of welding consumables, including specialized wire electrodes and shielding gases, to help achieve high-quality welds. With their comprehensive selection of welding supplies, welders can find everything they need for successful MIG welding projects.In addition to equipment and consumables, {Company Name} also places a strong emphasis on safety in welding. MIG welding produces intense heat and bright arcs, so it is crucial to use proper safety gear, such as welding helmets, gloves, and protective clothing. {Company Name} provides a range of high-quality safety products to ensure that welders can work with confidence and peace of mind.The versatility of MIG welding makes it suitable for a wide range of applications. It is commonly used in automotive repair and fabrication, as well as in manufacturing processes for various metal products. Whether it's joining steel components in a car chassis or fabricating aluminum structures, MIG welding offers a fast and efficient way to create strong and durable welds. With the right equipment and training, welders can master the art of MIG welding and excel in their respective fields.{Company Name} is dedicated to supporting welders with reliable products, technical expertise, and comprehensive training resources. They offer welding classes and workshops to help beginners learn the basics of MIG welding and improve their skills. Additionally, their team of technical specialists is available to provide guidance and technical support to customers, ensuring that they can achieve the best results with their MIG welding projects.In conclusion, MIG welding is a versatile and efficient welding technique that is widely used in various industries. With the right equipment, consumables, and training, welders can harness the power of MIG welding to create high-quality welds and achieve their project goals. {Company Name} is a trusted partner for welders, providing top-notch welding solutions and support to help them succeed in their welding endeavors. Whether it's for professional fabrication or DIY projects, {Company Name} has the expertise and resources to meet every welder's needs.

A Complete Guide to Arc Welding Process: Techniques and Benefits

The arc welding process is a tried and true method for joining metal workpieces together. It is a key component in the manufacturing and construction industries, as well as in the maintenance and repair of metal products. The process involves creating an electric arc between a welding electrode and the workpiece, which melts and fuses the metals together to form a strong and durable bond.One company that has made a name for itself in the field of arc welding is {}. With a strong emphasis on innovation and quality, {} has become a leading provider of arc welding solutions for a wide range of industries. The company offers a comprehensive range of welding equipment and consumables, as well as expert technical support and training services.The arc welding process can be divided into several different methods, each with its own unique characteristics and applications. For example, shielded metal arc welding (SMAW), also known as stick welding, is a popular and versatile technique that can be used for welding a variety of metals, including steel, stainless steel, and cast iron. Gas metal arc welding (GMAW), also known as MIG welding, is another commonly used method that is prized for its efficiency and ease of use. There is also gas tungsten arc welding (GTAW), also known as TIG welding, which is known for its precision and ability to produce high-quality welds.In addition to these traditional arc welding methods, {} has also developed advanced welding technologies that push the boundaries of what is possible with arc welding. One such innovation is the use of digital welding systems, which integrate advanced control and monitoring capabilities to improve the accuracy and consistency of the welding process. These systems allow for greater customization and control over the welding parameters, resulting in higher-quality welds and increased productivity.Another area of focus for {} is the development of specialized welding consumables, such as electrodes and filler metals, that are designed to meet the specific needs of different industries and applications. For example, the company offers a range of low hydrogen electrodes that are specifically formulated to reduce the risk of weld cracking in highly demanding applications, such as offshore construction and pressure vessel fabrication. {} also provides a wide selection of filler metals that are tailored to specific base metals and welding processes, ensuring optimal performance and quality in the finished welds.In addition to its cutting-edge welding products, {} is committed to providing comprehensive support and training to its customers. The company offers a range of technical services, including welding procedure development, welder certification, and on-site troubleshooting and support. {} also provides training programs that cover a wide range of topics, from basic welding techniques to advanced welding processes and technologies. These programs are designed to empower welders and welding engineers with the knowledge and skills they need to excel in their roles and deliver superior welding results.With a relentless focus on innovation, quality, and customer support, {} has established itself as a trusted partner for companies across a wide range of industries. Whether it is providing advanced welding equipment, developing specialized welding consumables, or delivering expert technical support and training, {} continues to push the boundaries of what is possible with arc welding. As the demand for high-quality welding solutions continues to grow, {} is well-positioned to play a key role in shaping the future of arc welding.

Learn the Basics of Stick Welding for Beginners

For individuals who are new to the world of welding, stick welding can be an excellent place to start. This method, also known as shielded metal arc welding (SMAW), is one of the most popular and widely used forms of welding due to its simplicity and versatility. Whether you are interested in pursuing welding as a hobby or as a potential career, learning the basics of stick welding can provide you with a strong foundation for more advanced techniques in the future.{Company} is a leading provider of welding equipment and supplies, committed to offering high-quality products and comprehensive support for welders of all skill levels. With a wide range of welding machines, consumables, and accessories available, {Company} is dedicated to meeting the needs of both professional welders and beginners alike.Stick welding is a highly versatile process that can be used to join a variety of metals, including steel, stainless steel, and cast iron. It is commonly used in construction, fabrication, and repair work, making it a valuable skill for anyone working in these industries. Additionally, stick welding can be performed in outdoor or windy conditions, making it an ideal choice for those who may not have access to a dedicated workshop or controlled environment.One of the key advantages of stick welding for beginners is its simplicity. The process involves striking an arc between the welding electrode (or "stick") and the workpiece, creating a molten pool that fuses the two pieces together. The slag produced during the welding process acts as a protective layer, shielding the weld from contaminants and impurities. This can be especially beneficial for beginners who are still refining their technique, as the slag can help cover any imperfections in the weld.{Company} offers a range of stick welding machines that are designed to be user-friendly and accessible for beginners. These machines are equipped with features that make them easy to set up and operate, allowing new welders to focus on developing their skills without being overwhelmed by complicated equipment. Additionally, {Company} provides a variety of welding electrodes in different sizes and types, ensuring that beginners have access to the right consumables for their specific welding needs.In addition to providing equipment and supplies, {Company} is committed to supporting aspiring welders through educational resources and training opportunities. The company offers workshops and demonstrations to help beginners learn the fundamentals of stick welding, as well as tips for improving their technique and achieving high-quality welds. These resources are invaluable for those who are just starting out and may benefit from expert guidance as they navigate the learning process.While stick welding can be a great starting point for beginners, it is important to approach the process with the proper safety precautions in mind. {Company} emphasizes the importance of using appropriate personal protective equipment, such as welding helmets, gloves, and clothing, to ensure the safety of all welders. Additionally, beginners should familiarize themselves with the correct techniques for handling and operating welding equipment to minimize the risk of accidents or injuries.As beginners progress in their stick welding journey, they may find opportunities to expand their skills and explore other forms of welding, such as MIG or TIG. {Company} is dedicated to supporting welders at every stage of their development, providing the equipment, expertise, and guidance needed to succeed in the field.In conclusion, stick welding can be a valuable and accessible technique for beginners who are interested in learning the art of welding. With the support of {Company} and its range of equipment, supplies, and educational resources, aspiring welders can gain the knowledge and experience they need to become proficient in stick welding and beyond. Whether pursuing welding as a hobby or a profession, beginners can trust {Company} to be their partner in the journey towards mastering this essential skill.

New Innovative Product Revolutionizes the Way You Smoke

Introducing the Next Generation of Portable Welding Technology: The Tig StickIn the world of welding, efficiency, versatility, and portability are key factors that can make or break a project. Fortunately, advances in technology have led to the development of innovative welding solutions that are revolutionizing the industry. One such innovation is the Tig Stick, a cutting-edge portable welding machine that is changing the game for welders across the globe.The Tig Stick, developed by a leading welding equipment company, is a compact and powerful welding machine that combines the functionality of both TIG and Stick welding processes into one sleek and portable unit. This ground-breaking technology allows welders to effortlessly switch between TIG and Stick welding modes, providing them with the flexibility to tackle a wide range of welding tasks with ease.At the heart of the Tig Stick is its advanced inverter technology, which delivers a smooth and stable arc for precise and high-quality welds. This technology also ensures that the Tig Stick is highly efficient, consuming less power and producing minimal heat, making it an eco-friendly choice for welders. In addition, the Tig Stick is equipped with a digital display that allows users to adjust welding parameters with precision and ease, giving them complete control over their welding operations.What sets the Tig Stick apart from other welding machines on the market is its portability. Weighing in at just a fraction of the weight of traditional welding machines, the Tig Stick is designed to be easily transported to any job site, whether it's in a workshop, on a construction site, or in a remote location. This level of portability means welders no longer have to be tied down to a stationary welding setup, giving them the freedom to work on a wide variety of projects without limitations.The Tig Stick is also built to withstand the rigors of the welding environment, with a rugged and durable construction that can handle the demands of heavy-duty welding applications. Its compact and lightweight design makes it easy to maneuver in tight spaces, while its robust build ensures that it can withstand the bumps and knocks that come with being on the move.In addition to its impressive technical features, the Tig Stick also comes with a range of accessories and optional add-ons, including a carry case, TIG torch, stick electrode holder, ground clamp, and protective welding gear. This comprehensive package provides welders with everything they need to get the job done, without having to invest in additional equipment.The Tig Stick is not just a tool for professional welders, it is also a great option for hobbyists, DIY enthusiasts, and small-scale workshops. Its user-friendly interface and intuitive controls make it suitable for welders of all skill levels, allowing them to achieve professional results with ease. Furthermore, its compact and portable design makes it an ideal choice for those who have limited space or need to take their welding equipment on the go.For those seeking a reliable, versatile, and portable welding solution, the Tig Stick is the answer. With its advanced technology, compact design, and comprehensive package, it is the perfect choice for welders who demand the best in performance and convenience. Whether it's for professional use or personal projects, the Tig Stick is a game-changer that is redefining the future of welding technology.

Innovative Gasless Tig Welding Machine for Efficient Welding

Gasless Tig Welding Machine Revolutionizes the Welding IndustryThe welding industry has seen a major innovation with the introduction of the Gasless Tig Welding Machine by {}. This cutting-edge technology has the potential to revolutionize the way welding is done, offering a more efficient and environmentally friendly alternative to traditional gas welding methods.The Gasless Tig Welding Machine is a game-changer in the industry, providing a cost-effective and efficient solution for welding applications. This innovative machine eliminates the need for gas cylinders, making it a more convenient and portable option for welders. The machine is capable of producing high-quality welds without the use of gas, making it an ideal choice for a wide range of welding projects.In addition to its gasless capabilities, the {} welding machine is also equipped with advanced features that enhance its performance and reliability. These features include a digital display for precise control and monitoring of welding parameters, as well as a built-in cooling system to ensure consistent weld quality. The machine also has a lightweight and compact design, making it easy to transport and set up in various work environments.The company {} behind this groundbreaking technology has established itself as a leader in the welding industry, with a strong commitment to innovation and quality. With a history of delivering high-quality welding equipment, the company has built a solid reputation for excellence in the industry. The introduction of the Gasless Tig Welding Machine further solidifies their position as a driving force in the welding technology sector.The Gasless Tig Welding Machine has already garnered significant attention and praise from welders and industry professionals. Many have recognized the machine's potential to streamline welding processes and improve productivity. With its ability to produce high-quality welds without the use of gas, the machine offers a more sustainable and eco-friendly solution for welding applications.The introduction of this advanced welding technology underscores the company's commitment to sustainability and environmental responsibility. By eliminating the need for gas cylinders, the Gasless Tig Welding Machine helps reduce the carbon footprint associated with traditional welding methods. This aligns with the company's dedication to promoting eco-friendly solutions and reducing the environmental impact of welding operations.Furthermore, the Gasless Tig Welding Machine is poised to make a significant impact on the welding industry, allowing welders to achieve superior results while also contributing to a cleaner and more sustainable environment. As the demand for greener technologies continues to grow, this innovative machine is well-positioned to meet the needs of the industry and drive positive change.In conclusion, the Gasless Tig Welding Machine by {} represents a major breakthrough in welding technology, offering a more efficient, cost-effective, and environmentally friendly alternative to traditional gas welding methods. With its advanced features and exceptional performance, this machine is set to transform the way welding is done and set new standards for excellence in the industry. As the driving force behind this innovative technology, the company {} continues to demonstrate its leadership and commitment to delivering cutting-edge solutions for the welding industry.

Advanced Multi Process Welding Machine for Efficient Welding

Innovative Multi Process Welding Machine Revolutionizes the Welding IndustryThe welding industry is constantly evolving as new technologies and advancements continue to shape the way we work with metals. One company that is leading the way in this evolution is [Company Name], a global leader in welding and cutting equipment. With their latest innovation, the Multi Process Welding Machine, they are once again setting new standards for efficiency, versatility, and performance in the welding industry.The Multi Process Welding Machine is a game-changer for welders, offering the ability to perform multiple types of welding processes with one machine. This not only saves time and space in the workshop, but also provides more flexibility and a wider range of capabilities for welders. Whether it's Stick welding, MIG welding, TIG welding, or flux-cored welding, this machine can do it all, making it a must-have tool for any professional welder.With the ability to switch between welding processes seamlessly, the Multi Process Welding Machine provides a level of convenience and efficiency that was previously unheard of in the industry. This means that welders can complete their jobs faster and with greater precision, ultimately increasing productivity and reducing overall project timelines.One of the key features of the Multi Process Welding Machine is its user-friendly interface, which allows welders to easily select and adjust their welding parameters for each specific welding process. This level of control enables welders to achieve the perfect weld for any given application, ensuring top-quality results every time.In addition to its versatility and user-friendly design, the Multi Process Welding Machine also boasts advanced technology that enhances the welding experience. With features such as digital display screens, built-in safety mechanisms, and efficient power sources, this machine is at the forefront of welding technology, providing welders with the tools they need to excel in their craft.[Company Name] is proud to be at the forefront of this technological innovation in the welding industry and is committed to providing welders with the best equipment available. With a strong focus on research and development, the company has a long-standing reputation for delivering cutting-edge welding solutions that meet the ever-changing needs of the industry.Having been in the welding equipment business for several decades, [Company Name] has a deep understanding of the challenges that welders face on a daily basis. This knowledge has allowed them to design and manufacture equipment that not only meets the demands of the industry but also exceeds expectations in terms of performance and durability.The Multi Process Welding Machine is a testament to [Company Name]'s dedication to providing welders with the tools they need to succeed. By combining their expertise in welding technology with a commitment to innovation, they have created a product that is truly revolutionary in the welding industry.As the industry continues to evolve, [Company Name] remains committed to staying ahead of the curve, continuously pushing the boundaries of what is possible in welding technology. With the Multi Process Welding Machine, they have once again demonstrated their ability to lead the way in revolutionizing the welding industry.In conclusion, the Multi Process Welding Machine from [Company Name] represents a significant advancement in welding technology. With its versatility, user-friendly design, and advanced features, this machine is poised to make a lasting impact on the industry. By providing welders with the tools they need to work more efficiently and effectively, [Company Name] is helping to shape the future of welding.

High-Quality Welding Ventilation Hood: What You Need to Know

Welding Ventilation Hood: Paving the Way for Safer Work EnvironmentsIn today's fast-paced industrial world, workplace safety is of paramount importance. For companies involved in welding and metal fabrication, ensuring the safety and well-being of their employees is not just a priority, but a legal obligation. This is where [Company Name]'s Welding Ventilation Hood comes into play, paving the way for safer work environments and setting new standards in the industry.Established in [year], [Company Name] has been at the forefront of providing innovative solutions for industrial ventilation and air quality control. With a strong focus on research and development, the company has continuously strived to address the unique challenges faced by industries such as welding and metal fabrication. The result of this dedication to excellence is the Welding Ventilation Hood, a product that has revolutionized the way companies approach workplace safety.The Welding Ventilation Hood is designed to effectively capture and filter out the hazardous fumes and particulates produced during welding and metal fabrication processes. Equipped with state-of-the-art technology, the ventilation hood ensures that workers are not exposed to harmful airborne contaminants, thus reducing the risk of respiratory problems and other health issues associated with prolonged exposure to welding fumes.One of the key features of the Welding Ventilation Hood is its high-efficiency particulate air (HEPA) filters, which are capable of capturing up to 99.97% of particles as small as 0.3 microns. This level of filtration is essential in maintaining a clean and safe work environment, especially in industries where workers are constantly exposed to fumes and airborne contaminants. Additionally, the ventilation hood is equipped with a powerful extraction system that quickly removes fumes from the work area, further enhancing worker safety and comfort.In addition to its cutting-edge filtration and extraction capabilities, the Welding Ventilation Hood also boasts a robust and user-friendly design. The hood is constructed from durable materials that can withstand the rigors of industrial use, and its ergonomic features make it easy to install and operate. Moreover, the ventilation hood can be customized to fit the specific needs of different work environments, ensuring a tailored solution for every customer.The impact of the Welding Ventilation Hood on workplace safety has been nothing short of remarkable. Companies that have implemented the ventilation hood have reported significant improvements in air quality and worker satisfaction. By providing a cleaner and safer work environment, the hood has not only helped companies comply with occupational health and safety regulations, but has also boosted productivity and morale among employees.Furthermore, [Company Name] has also provided comprehensive training and support services to ensure that customers are able to maximize the benefits of the Welding Ventilation Hood. From installation and maintenance to troubleshooting and replacement parts, the company's team of experts is dedicated to helping customers make the most of their investment in workplace safety.Looking ahead, [Company Name] remains committed to pushing the boundaries of innovation and setting new benchmarks for workplace safety. The Welding Ventilation Hood is just one example of the company's ongoing efforts to provide cutting-edge solutions that make a tangible difference in the lives of workers. As the industry continues to evolve, [Company Name] is poised to lead the way, shaping the future of industrial ventilation and air quality control.In conclusion, [Company Name]'s Welding Ventilation Hood stands as a testament to the company's unwavering commitment to excellence and dedication to creating safer work environments. By addressing the unique challenges faced by industries such as welding and metal fabrication, the ventilation hood has set new standards for workplace safety, and its impact will undoubtedly be felt for years to come. As companies increasingly recognize the importance of prioritizing the health and well-being of their employees, the Welding Ventilation Hood is poised to become an indispensable asset in the quest for a safer and more productive industrial landscape.

The Top Tig Welders You Need to Know About

Top Tig Welders Vying for the TitleTig welding is a specialized welding process that requires skill, precision, and expertise. As the demand for high-quality welding continues to rise, the competition among top Tig welders has become increasingly intense. Several welders have emerged as frontrunners, showcasing their exceptional skills and expertise in the field. Among the top contenders include welders from {}, a renowned company that has been at the forefront of delivering exceptional welding solutions for a wide range of industries.{} is a leading provider of welding equipment, known for its innovation and commitment to excellence. The company has a long-standing reputation for producing top-of-the-line Tig welders that are trusted by professionals around the world. With a focus on quality and performance, {} has garnered a loyal customer base and continues to set the bar high for welders in the industry.In a recent competition to determine the top Tig welders, several skilled professionals from {} stepped up to showcase their exceptional talent and expertise. These welders have undergone rigorous training and have honed their skills to perfection, making them formidable competitors in the field. With a combination of technical prowess and practical experience, {} welders have demonstrated their ability to handle complex welding projects with precision and finesse.One of the standout welders from {} is John Smith, a seasoned professional with over 15 years of experience in Tig welding. Smith has consistently impressed his peers and clients with his exceptional welding skills and attention to detail. His ability to produce flawless welds with a high level of accuracy and consistency has earned him a reputation as one of the top Tig welders in the industry.Another standout performer from {} is Sarah Brown, a rising star in the world of Tig welding. Brown's keen eye for detail and her ability to handle intricate welding tasks with ease have set her apart as a top contender in the field. Her dedication to mastering the art of Tig welding and her commitment to delivering impeccable results have solidified her position as a force to be reckoned with.The competition among top Tig welders is fierce, with each participant vying for the coveted title of the best in the industry. The judges are looking for welders who can demonstrate exceptional skill, precision, and innovation in their welding techniques. With the high stakes and the pressure to perform at their best, welders from {} are leaving no stone unturned in their quest to claim the top spot.As the competition heats up, {} remains committed to supporting its talented team of welders and providing them with the tools and resources they need to succeed. The company's dedication to excellence and its unwavering support for its employees have helped propel its welders to the forefront of the industry. With a combination of cutting-edge technology and a team of highly skilled professionals, {} is well-positioned to maintain its status as a leader in Tig welding solutions.The top Tig welders from {} are ready to showcase their exceptional skills and compete for the title of the best in the industry. With their unwavering dedication to excellence and their commitment to delivering top-quality welding results, these welders are poised to make a lasting impression on the judges and their peers. As the competition unfolds, all eyes are on the talented welders from {}, as they continue to raise the bar for Tig welding excellence.

High-Performance IGBT DC Inverter Welder for Professional Use

The IGBT DC Inverter Welder is a cutting-edge welding machine that is revolutionizing the welding industry. This advanced welding technology is making it easier and more efficient for welders to join metals together, whether it be for construction, manufacturing, or automotive purposes.The IGBT DC Inverter Welder utilizes Insulated Gate Bipolar Transistor (IGBT) technology, allowing for a more precise and stable welding process. With its direct current (DC) output, this welder provides a smooth and consistent arc, resulting in high-quality welds with minimal spatter and distortion.One of the key features of the IGBT DC Inverter Welder is its portability and lightweight design. This makes it convenient for welders to carry and use the machine in various locations, whether it be on construction sites or in a workshop. The compact size of the welder also allows for easy storage when not in use.In addition to its portability, the IGBT DC Inverter Welder is also known for its energy efficiency. The IGBT technology enables the welder to deliver high levels of power with minimal energy consumption. This not only saves on electricity costs but also reduces the environmental impact of welding processes.Furthermore, the IGBT DC Inverter Welder is designed for versatility, allowing for a wide range of welding applications. Whether it be for stick welding, TIG welding, or even plasma cutting, this welding machine can handle various tasks with ease. This versatility makes it an ideal choice for welders who work on diverse projects that require different welding techniques.Moreover, the IGBT DC Inverter Welder is also praised for its user-friendly interface and advanced features. With digital displays and intuitive controls, welders can easily adjust settings and monitor the welding process in real-time. This ensures greater precision and control, resulting in consistently high-quality welds.With its advanced technology and practical design, the IGBT DC Inverter Welder has garnered widespread attention and praise within the welding industry. As a result, it has become a popular choice for professional welders and workshops alike.In light of the growing demand for the IGBT DC Inverter Welder, \ is proud to introduce their own line of these cutting-edge welding machines. With years of experience in the welding equipment industry, \ has established itself as a trusted and reliable supplier of high-quality welding products.\ is dedicated to providing welders with the latest advancements in welding technology, and their line of IGBT DC Inverter Welders is a testament to this commitment. By partnering with leading manufacturers and conducting rigorous quality control, they ensure that their welders meet the highest standards of performance and durability.Moreover, \ offers a range of IGBT DC Inverter Welders to suit the specific needs of different welders. Whether it be for professional welders working on industrial projects or hobbyists seeking a reliable welding machine for personal use, \ has a solution for every welding application.In addition to offering top-of-the-line welding equipment, \ also prides itself on providing exceptional customer service and technical support. Their team of experienced professionals is ready to assist welders with any questions or concerns they may have, ensuring a positive experience with their products.As the welding industry continues to evolve, the IGBT DC Inverter Welder stands out as a game-changing technology that is reshaping the way welders work. With its advanced features, portability, energy efficiency, and versatility, this welding machine is proving to be a valuable asset for welders across various industries.For welders looking to upgrade their equipment and take their welding skills to the next level, the IGBT DC Inverter Welder offered by \ is a top choice. With their dedication to quality and innovation, \ is poised to lead the way in providing welders with the tools they need to succeed in their craft.

Highly Efficient Dc Inverter Welder for Precision Welding

DC Inverter Welder Revolutionizing the Welding IndustryWith advancements in technology, the welding industry has seen significant improvements in the efficiency and effectiveness of welding equipment. One such innovation that has taken the industry by storm is the DC Inverter Welder. This cutting-edge welding machine has been making waves in the industry, offering numerous benefits and advantages to professionals and enthusiasts alike.The DC Inverter Welder utilizes a high-frequency direct current (DC) to produce a stable and efficient welding arc. This technology enables the welder to produce high-quality welds with greater precision and control. Unlike traditional welding machines, the DC Inverter Welder is compact, lightweight, and portable, making it ideal for on-site welding applications.One of the key features of the DC Inverter Welder is its ability to deliver a smooth and stable welding arc, resulting in clean and uniform welds. This is particularly beneficial for welding thin materials or performing intricate welding tasks that require precision and finesse. Additionally, the advanced inverter technology allows for better control over the welding process, leading to improved weld quality and reduced spatter.The efficiency of the DC Inverter Welder is another standout feature. With its high-frequency DC output, the welder consumes less power and produces less heat, resulting in energy savings and a cooler working environment. This not only reduces operating costs but also improves the overall welding experience for the user.Furthermore, the portability of the DC Inverter Welder makes it a versatile and convenient tool for professionals who need to work in various locations. Its compact design and lightweight construction make it easy to transport, allowing welders to take on a wide range of welding projects with ease.In addition to its technical capabilities, the DC Inverter Welder is backed by the reputable company {}. With years of experience in the welding industry, {} has earned a solid reputation for producing high-quality welding equipment and providing exceptional customer service.The company's commitment to innovation and excellence is evident in the design and performance of the DC Inverter Welder. By leveraging their expertise and technical know-how, {} has developed a welding machine that meets the demands of modern welding applications and exceeds the expectations of professionals in the industry.As a leader in the welding equipment market, {} continues to invest in research and development to further enhance the capabilities of the DC Inverter Welder. The company's dedication to continuous improvement and customer satisfaction sets them apart as a reliable and trusted provider of welding solutions.In conclusion, the DC Inverter Welder has undoubtedly raised the bar for welding equipment, offering a combination of advanced technology, performance, and portability. With its superior welding capabilities and the backing of a reputable company like {}, the DC Inverter Welder is set to revolutionize the welding industry and empower professionals to take on new welding challenges with confidence.For more information about the DC Inverter Welder and other welding solutions from {}, please visit their website or contact their customer support team.