Powerful and Affordable AC DC Tig Welder for Budget-Friendly Welding

By:Admin

Introducing the New Budget-Friendly AC DC TIG Welder

In today’s fast-paced and ever-evolving manufacturing industry, the demand for reliable and efficient welding equipment has never been greater. As companies strive to meet production deadlines and maintain high standards of quality, the need for advanced welding technology that is both cost-effective and easy to use has become increasingly important. This is where the latest offering from {Company Name} comes into play: the budget-friendly AC DC TIG welder.

The new AC DC TIG welder, which is designed to meet the needs of both professional welders and hobbyists, features a combination of innovative technology, user-friendly interface, and rugged construction, all at an affordable price point. Whether you are working on stainless steel, aluminum, or other materials, this versatile welding machine is capable of delivering precise and reliable results with its advanced AC/DC welding capabilities.

One of the key benefits of this new AC DC TIG welder is its ability to switch between AC and DC modes, making it ideal for a wide range of welding applications. Whether you are tackling thin materials or thick plates, the welder provides excellent arc stability and control, allowing for clean and smooth welds. In addition, the inclusion of pulse mode and adjustable frequency settings further enhances the welder’s versatility, allowing users to customize their welding parameters according to specific job requirements.

Furthermore, the intuitive control panel of the welder is designed to simplify the welding process, with user-friendly knobs and buttons that allow for easy adjustment of welding parameters. This ensures that even less-experienced welders can quickly master the machine and achieve consistent and high-quality results. Additionally, the welder’s compact and portable design makes it suitable for both workshop and on-site welding applications, further enhancing its practicality and convenience.

As with all products from {Company Name}, the new budget-friendly AC DC TIG welder is built to withstand the rigors of daily industrial use. Its robust construction and high-quality components ensure long-term reliability and performance, making it a valuable investment for any welding professional or enthusiast. Furthermore, the welder comes with a comprehensive warranty and after-sales support from {Company Name}, providing customers with the peace of mind and confidence that their welding needs are well taken care of.

The release of the new budget-friendly AC DC TIG welder highlights {Company Name}’s commitment to delivering innovative and high-quality welding solutions that cater to the diverse needs of today’s welders. With a focus on affordability, ease of use, and performance, the welder is expected to be a popular choice among welding professionals and hobbyists alike.

In conclusion, the launch of the new budget-friendly AC DC TIG welder from {Company Name} represents a significant advancement in welding technology, offering a compelling combination of advanced features, user-friendly design, and rugged reliability at an accessible price point. Whether you are a seasoned welder looking to upgrade your equipment or a beginner seeking a reliable and cost-effective welding solution, this new welder is set to make a strong impact in the welding industry. With its versatility, performance, and affordability, the new AC DC TIG welder is poised to become a valuable asset for welders across a wide range of industries.

Company News & Blog

High-Quality Heavy-Duty Welding Holder for Welding Jobs

Welding Holder Heavy Duty: The Perfect Solution for Your Welding NeedsWelding is a critical process in many industries, and having the right tools and equipment is essential to ensuring high-quality and efficient results. A welding holder is a crucial component of any welding setup, providing a secure and stable grip for the welding electrode or rod. When it comes to heavy-duty welding holders, there is one name that stands out from the rest – {company name}.{Company Name} is a leading manufacturer of welding equipment and accessories, specializing in high-quality, reliable products that meet the needs of professional welders across the globe. With a commitment to innovation and customer satisfaction, {company name} has built a solid reputation for delivering excellence in the welding industry.The {company name} welding holder heavy-duty is a prime example of the company’s dedication to product quality and performance. Designed to withstand the most demanding welding applications, this welding holder is built to last, providing welders with the durability and reliability they need to get the job done right.One of the key features of the {company name} welding holder heavy-duty is its robust construction. Made from high-quality materials, this welding holder is built to handle tough working conditions and heavy use, providing welders with a tool they can depend on day in and day out. The strong clamping force ensures that the welding electrode or rod remains securely in place, allowing for precise and controlled welding.In addition to its exceptional durability, the {company name} welding holder heavy-duty also offers superior performance. The ergonomic design and comfortable grip make it easy to handle, reducing fatigue and improving overall productivity. The high conductivity ensures efficient power transfer, allowing for smooth and consistent welding results. Whether you are working on a small fabrication project or a large-scale welding job, this welding holder is up to the task.{Company Name} takes pride in its commitment to customer satisfaction, and the welding holder heavy-duty is no exception. The company stands behind its products, offering a warranty and comprehensive customer support to ensure that welders are completely satisfied with their purchase. The {company name} team is dedicated to providing expert advice and guidance, helping customers find the right welding solutions for their specific needs.With its focus on quality, performance, and customer service, {company name} has earned the trust and loyalty of professional welders around the world. The {company name} welding holder heavy-duty is just one example of the company’s dedication to excellence, and it is a valuable addition to any welding operation.As the demand for high-quality welding solutions continues to grow, {company name} remains at the forefront of the industry, leading the way with innovative products and superior performance. The welding holder heavy-duty is a testament to the company’s unwavering commitment to providing welders with the tools they need to succeed.In conclusion, the {company name} welding holder heavy-duty is a top-of-the-line product that delivers exceptional durability, performance, and reliability. With its robust construction, superior conductivity, and ergonomic design, this welding holder is the perfect solution for professional welders seeking a heavy-duty, long-lasting tool. Backed by {company name}’s reputation for excellence and customer satisfaction, the welding holder heavy-duty is a valuable investment for any welding operation.

Essential Guide to Welding Gas Regulators: How to Choose, Use, and Maintain

Welding Gas Regulator Recalled Due to Safety Concerns[Company Name] has recently issued a recall for their welding gas regulators due to safety concerns. The company, known for producing high-quality welding equipment, has identified a potential issue with these regulators that could pose a safety risk to users. The recall has been initiated in order to prevent any accidents or injuries that could occur as a result of this issue.The affected welding gas regulators are designed for use in various welding applications, and are commonly used in industrial settings as well as by individual hobbyists. The regulators are used to control the flow of gas to the welding torch, and are an essential piece of equipment for ensuring the safety and effectiveness of the welding process.The specific issue that has prompted the recall is related to the potential for gas leakage from the regulators. This could result in a release of flammable gas, which poses a significant fire hazard. In addition, the leakage of gas could also create a risk of exposure to harmful fumes, which could pose a health risk to users.In response to this issue, [Company Name] is urging all customers who have purchased the affected welding gas regulators to stop using them immediately and to return them to the company for a full refund. The company is also working to contact all known purchasers of the affected regulators in order to inform them of the recall and provide them with instructions on how to return the product.[Company Name] takes the safety of its customers very seriously and is committed to ensuring that all of its products meet the highest standards of quality and reliability. The company has apologized for any inconvenience that this recall may cause to its customers, and is working to resolve the issue as quickly as possible.In the meantime, [Company Name] is advising all users of welding gas regulators to inspect their equipment for signs of the issue, such as unusual odors or evidence of gas leakage. If any such signs are present, users should discontinue use of the regulator immediately and contact the company for further instructions.The recall of these welding gas regulators serves as a reminder of the importance of ensuring the safety and reliability of all welding equipment. Users are encouraged to always carefully inspect their equipment for any signs of damage or malfunction, and to follow all recommended maintenance and safety procedures. By taking these precautions, users can help to prevent accidents and injuries and ensure the safe and effective operation of their welding equipment.As [Company Name] works to address this issue and provide a resolution for affected customers, the company remains committed to upholding its reputation for producing high-quality, reliable welding equipment. With a focus on safety and customer satisfaction, the company continues to strive for excellence in the design and manufacturing of its products.In conclusion, the recall of the welding gas regulators by [Company Name] serves as a reminder of the importance of safety and quality in welding equipment. The company is working diligently to address the issue and provide a resolution for its customers, while also emphasizing the importance of proper equipment inspection and maintenance for all users of welding equipment. By taking these precautions, users can help to ensure their safety and the effectiveness of their welding operations.

Advanced MMA Cut Welding Machine for Tig Welding - A Complete Overview

Tig MMA Cut Welding Machine Revolutionizes the Welding IndustryThe welding industry has seen a significant transformation with the introduction of the Tig MMA Cut welding machine by a leading welding equipment manufacturer. This advanced welding machine is set to revolutionize the way welding is carried out, offering a range of benefits that make it a game-changer in the industry.The Tig MMA Cut welding machine is designed to provide advanced welding capabilities, making it suitable for a wide range of welding applications. Whether it is precision welding, heavy-duty welding, or even plasma cutting, this machine has the capability to handle it all with utmost precision and efficiency. With its advanced technology and state-of-the-art features, this welding machine is sure to become a go-to choice for both amateur and professional welders.One of the key features of the Tig MMA Cut welding machine is its versatility. It is capable of handling various welding processes, including TIG welding, MMA welding, and plasma cutting. This versatility makes it a valuable tool for welders who need to work on different types of projects, as it eliminates the need for multiple machines.Additionally, the Tig MMA Cut welding machine is designed with user convenience in mind. It features an intuitive interface and user-friendly controls, making it easy to operate even for those who are new to welding. The machine also incorporates advanced safety features, ensuring that operators can work with peace of mind.Furthermore, the Tig MMA Cut welding machine is built to last. It is constructed with high-quality materials and components, ensuring durability and reliability even in the most demanding work environments. This means that welders can rely on this machine to deliver consistent performance and quality results, project after project.In addition to its impressive capabilities, the Tig MMA Cut welding machine is also designed with energy efficiency in mind. It is equipped with advanced power management features that minimize energy consumption without compromising on performance. This not only reduces operating costs but also makes it an environmentally friendly choice for welding professionals.The introduction of the Tig MMA Cut welding machine by {} represents a significant milestone for the company. With a commitment to innovation and excellence, the company has established itself as a leader in the welding equipment industry. The launch of this advanced welding machine is a testament to the company's dedication to providing cutting-edge solutions that meet the evolving needs of welders worldwide.The Tig MMA Cut welding machine is expected to have a profound impact on the welding industry, setting a new standard for welding precision, efficiency, and versatility. It is set to become a go-to choice for welders across various sectors, including automotive, construction, manufacturing, and more.With its advanced capabilities, user-friendly design, and robust construction, the Tig MMA Cut welding machine is poised to redefine the way welding is carried out. It is a testament to the continuous advancements in welding technology, and it is set to empower welders to achieve exceptional results like never before.In conclusion, the Tig MMA Cut welding machine is a game-changing innovation in the welding industry. With its advanced capabilities, user-friendly design, and energy-efficient operation, it is set to become a go-to choice for welders worldwide. As the industry continues to evolve, this machine represents a step forward in welding technology, empowering welders to take on a wide range of projects with confidence and precision.

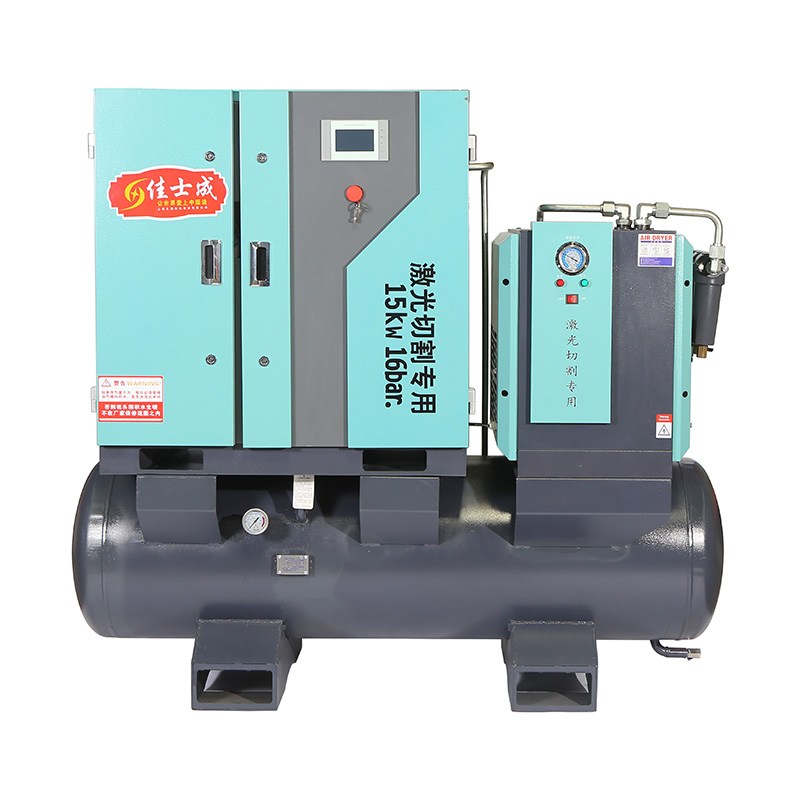

High-Quality Medical Air Compressor for Healthcare Facilities

Medical Air Compressor Enhancing Healthcare ServicesIn the world of healthcare, reliable and efficient equipment is crucial for providing quality care to patients. One such piece of equipment that plays a vital role in healthcare facilities is the medical air compressor. These compressors are used to provide a clean and continuous supply of compressed air for various medical devices and procedures, making them an essential component of any hospital or clinic.One company that has been at the forefront of providing high-quality medical air compressors is [Brand Name Removed]. With a long history of innovation and a strong commitment to enhancing healthcare services, [Brand Name Removed] has established itself as a trusted provider of medical equipment solutions.Founded in [year], [Brand Name Removed] has spent decades developing and manufacturing advanced medical air compressors that meet the stringent standards of the healthcare industry. The company's dedication to research and development has resulted in a range of products that are known for their reliability, performance, and efficiency. As a result, [Brand Name Removed] has become a preferred choice for healthcare facilities looking for dependable medical air compressor solutions.One of the key features of [Brand Name Removed] medical air compressors is their ability to deliver a consistent supply of high-quality compressed air. This is essential for various medical applications, including respiratory therapy, surgical tools, and patient monitoring systems. By ensuring a clean and reliable air supply, [Brand Name Removed] medical air compressors contribute to the overall safety and effectiveness of patient care.Moreover, [Brand Name Removed] medical air compressors are designed with the latest technology to minimize noise and vibration, making them suitable for use in a variety of healthcare settings. The company's commitment to user comfort and convenience is evident in the thoughtful design and ergonomic features of their medical air compressors.In addition to their technical capabilities, [Brand Name Removed] medical air compressors are also known for their durability and low maintenance requirements. This is an important consideration for healthcare facilities, as it allows for uninterrupted operation and reduces the cost of ownership over time.Furthermore, [Brand Name Removed] places a strong emphasis on compliance with industry standards and regulations. Their medical air compressors are designed and manufactured in accordance with the strictest quality and safety standards, ensuring that they meet the needs of healthcare professionals and their patients.In line with their mission to enhance healthcare services, [Brand Name Removed] also provides comprehensive support and services for their medical air compressors. This includes installation, training, maintenance, and technical assistance, ensuring that healthcare facilities can rely on their equipment for seamless and efficient operation.Looking ahead, [Brand Name Removed] continues to invest in research and development to further improve their medical air compressors and introduce new, innovative solutions to meet the evolving needs of the healthcare industry. By staying at the forefront of technology and industry best practices, the company remains committed to empowering healthcare providers with the tools they need to deliver exceptional patient care.In conclusion, [Brand Name Removed] has established itself as a leading provider of medical air compressors that play a critical role in enhancing healthcare services. With a focus on reliability, performance, and compliance, the company's medical air compressors are trusted by healthcare facilities worldwide. Through ongoing innovation and a dedication to customer support, [Brand Name Removed] continues to set the standard for medical equipment solutions in the healthcare industry.

Compact Electric Welder: A Game-Changer in the Welding Industry

Mini Electric Welder Revolutionizes the Welding IndustryIn a world where technology is constantly evolving, it is no surprise that the welding industry is also seeing a transformation. The emergence of the Mini Electric Welder has taken the industry by storm, providing a compact and efficient solution for both professionals and hobbyists alike.With its compact size and powerful performance, the Mini Electric Welder has become a game-changer in the welding industry. This revolutionary product has been developed by a leading company that specializes in manufacturing cutting-edge welding equipment. The company, with its years of experience and expertise, has been at the forefront of innovation in the welding industry. Their dedication to research and development has led to the creation of the Mini Electric Welder, a product that has set new standards for efficiency, convenience, and quality in welding.One of the most striking features of the Mini Electric Welder is its compact size. Measuring just a fraction of the size of traditional welding machines, this mini welder is highly portable and easy to transport. This makes it an ideal choice for on-the-go professionals who need to take their welding equipment to different job sites.Despite its small size, the Mini Electric Welder packs a powerful punch. Equipped with advanced technology, this welding machine delivers high-performance welding capabilities that rival those of larger, bulkier machines. This means that users can enjoy the convenience of a mini welder without sacrificing the quality of their work.In addition to its portability and performance, the Mini Electric Welder is also designed with user-friendly features that make it accessible to welders of all skill levels. With intuitive controls and a straightforward interface, this welding machine is easy to operate, making it a great option for both experienced professionals and beginners.Furthermore, the Mini Electric Welder is equipped with safety features that prioritize the well-being of its users. From automatic shut-off mechanisms to overheat protection, this welding machine is designed to provide a secure and reliable welding experience.The Mini Electric Welder has already made a significant impact in the welding industry, receiving rave reviews from users who have praised its efficiency and convenience. As a result, it has quickly become a top choice for welding professionals and DIY enthusiasts who are looking for a versatile and reliable welding solution.With its innovative design and cutting-edge technology, it is clear that the Mini Electric Welder is poised to revolutionize the welding industry. As the demand for portable and efficient welding solutions continues to grow, this mini welder is well-positioned to meet the needs of a diverse range of users.The company behind the Mini Electric Welder is committed to leading the way in welding technology, and their innovative approach has positioned them as a driving force in the industry. With a focus on quality, performance, and user experience, they continue to set new standards for welding equipment, pushing the boundaries of what is possible in the field.In conclusion, the Mini Electric Welder has emerged as a groundbreaking product that is reshaping the welding industry. With its compact size, powerful performance, and user-friendly features, it has become a go-to choice for welders who are looking for a convenient and reliable welding solution. As the industry continues to evolve, the Mini Electric Welder and the company behind it are at the forefront of innovation, setting a new standard for excellence in welding technology.

High-Performance IGBT DC Inverter Welder for Precision Welding

The innovative IGBT DC Inverter Welder has caught the attention of welding professionals and enthusiasts alike. This cutting-edge welding machine has been garnering praise for its advanced technology and superior performance in the welding industry.The IGBT DC Inverter Welder is a game-changer in the field of welding equipment. It is equipped with Insulated Gate Bipolar Transistor (IGBT) technology, which allows for higher efficiency and better control over the welding process. This technology ensures smooth and stable welding operations, making it a preferred choice for professional welders and DIY enthusiasts.The compact and lightweight design of the IGBT DC Inverter Welder makes it easy to transport and handle, making it an ideal choice for both on-site and workshop welding projects. Despite its small size, this welder packs a powerful punch, delivering high-quality welds with excellent precision and minimal spatter.One of the standout features of the IGBT DC Inverter Welder is its ability to weld a wide range of materials, including steel, stainless steel, and aluminum, with exceptional ease and efficiency. This versatile welding machine offers a wide amperage range, allowing users to tackle a variety of welding tasks with precision and accuracy.In addition to its impressive performance, the IGBT DC Inverter Welder is also lauded for its energy efficiency and cost-effectiveness. The IGBT technology used in this welder allows for a more efficient use of power, resulting in lower energy consumption and reduced operating costs. This makes it an attractive option for businesses and welding professionals looking to optimize their welding operations.The company behind the development of the IGBT DC Inverter Welder, {Company}, is a renowned industry leader in welding equipment and technology. With a strong focus on innovation and customer satisfaction, {Company} has established itself as a trusted provider of high-quality welding solutions.{Company} takes pride in its commitment to delivering cutting-edge welding equipment that meets the highest standards of quality and performance. The IGBT DC Inverter Welder is a testament to the company's dedication to pushing the boundaries of welding technology, providing users with advanced tools that empower them to achieve exceptional results.The IGBT DC Inverter Welder is just one of the many innovations produced by {Company} that have earned recognition and acclaim in the welding industry. With a strong emphasis on research and development, {Company} continues to set new benchmarks for welding equipment, setting itself apart as a market leader in the field.As the demand for efficient and versatile welding equipment continues to grow, the IGBT DC Inverter Welder has emerged as a top choice for professionals and enthusiasts seeking a reliable and high-performance welding solution. With its advanced technology, compact design, and exceptional capabilities, this welder is poised to make a significant impact in the welding industry.In conclusion, the IGBT DC Inverter Welder from {Company} represents a new standard of excellence in welding technology. Its advanced features, superior performance, and energy-efficient design make it a standout choice for a wide range of welding applications. As {Company} continues to lead the way in welding innovation, the IGBT DC Inverter Welder stands as a testament to the company's unwavering commitment to delivering top-notch welding solutions.

The latest advances in welding machine technology

All Welding Machine Leads the Industry with Cutting-Edge Technology and Superior QualityIn the fiercely competitive world of welding equipment, one company stands out from the rest: All Welding Machine. With a strong commitment to innovation, quality, and customer satisfaction, All Welding Machine has established itself as a leader in the industry. Their dedication to excellence and their ability to stay ahead of the curve in terms of technology and design have made them a trusted name among welders and fabricators worldwide.All Welding Machine was founded in 1985 by a team of industry veterans who saw a need for a new approach to welding equipment. Their goal was to create a line of products that would not only meet the needs of professional welders but also exceed their expectations. To achieve this, they invested heavily in research and development, working tirelessly to design and build welding machines that would outperform anything else on the market.One of the key factors in the success of All Welding Machine is their unwavering commitment to using the latest technology in their products. By staying at the forefront of technological advancements, they have been able to consistently deliver cutting-edge welding equipment that provides superior performance and reliability. Their welding machines are known for their precision, power, and durability, making them the top choice for a wide range of applications, from automotive and aerospace to manufacturing and construction.In addition to their focus on technology, All Welding Machine is also dedicated to ensuring the highest quality in every aspect of their business. From the materials they use to the manufacturing processes they employ, they maintain strict standards to ensure that their products are of the highest quality. This commitment to excellence has earned them a reputation for reliability and dependability, further solidifying their position as a leading manufacturer of welding equipment.One of the things that sets All Welding Machine apart from the competition is their dedication to customer satisfaction. They understand that their success is directly tied to the success of their customers, and they go above and beyond to meet their needs. From providing exceptional customer service to offering comprehensive training and support, they do everything in their power to ensure that their customers have a positive experience with their products.All Welding Machine's commitment to excellence and innovation has not gone unnoticed. They have received numerous accolades and awards for their products, and they continue to earn the trust and loyalty of welders and fabricators around the world. Their products are widely regarded as the gold standard in the industry, and they are consistently chosen by professionals who demand the best.Looking to the future, All Welding Machine remains focused on pushing the boundaries of what is possible in welding technology. They continue to invest in research and development, exploring new materials, processes, and design concepts to create the next generation of welding equipment. Their goal is to continue to lead the industry and provide their customers with the tools they need to succeed.In conclusion, All Welding Machine is a company that has set the bar for excellence in the welding equipment industry. Their dedication to innovation, quality, and customer satisfaction has made them a trusted name among professionals, and their products are widely regarded as the best in the business. With their unwavering commitment to excellence and their focus on the future, they are well-positioned to continue leading the industry for years to come.

High-Performance IGBT Inverter Welder for Efficient Welding

{Company Name}, a leading manufacturer of welding equipment, has recently launched its latest product, the IGBT Inverter Welder. This cutting-edge welding machine is designed to provide superior performance and flexibility for professional welders across various industries.The IGBT Inverter Welder from {Company Name} is a powerful and versatile welding machine that utilizes insulated gate bipolar transistors (IGBT) technology to deliver high efficiency and precision in the welding process. With its advanced inverter technology, this welder offers stable and smooth welding output, making it suitable for a wide range of welding applications, including metal fabrication, automotive repair, construction, and more.One of the key features of the IGBT Inverter Welder is its compact and lightweight design, which makes it highly portable and easy to transport to different job sites. This allows welders to work efficiently in various locations without the hassle of bulky and heavy equipment. Additionally, the welder is equipped with a digital control interface that provides users with the ability to adjust welding parameters easily and accurately, ensuring optimal performance and weld quality.Furthermore, the IGBT Inverter Welder is built with robust construction and advanced thermal management to withstand harsh working environments and prolonged use. This ensures the durability and reliability of the machine, even in the most demanding welding conditions. With its high duty cycle and low power consumption, this welder is not only efficient in operation but also helps to reduce energy costs for users.In addition to its exceptional performance, the IGBT Inverter Welder is designed with user safety in mind. The machine features built-in protections against overcurrent, overheating, and short circuits, providing welders with peace of mind during operation. Moreover, {Company Name} offers comprehensive technical support and a warranty for the IGBT Inverter Welder, ensuring customers have access to reliable assistance and service.As a reputable manufacturer of welding equipment, {Company Name} has a strong commitment to innovation and quality in its products. The introduction of the IGBT Inverter Welder further demonstrates the company's dedication to meeting the evolving needs of the welding industry and providing welders with advanced solutions to enhance their productivity and performance.{Company Name} emphasizes that the IGBT Inverter Welder is the result of extensive research and development, leveraging the latest technological advancements to deliver a welding machine that sets new standards in the industry. With its focus on precision, efficiency, and reliability, this welder is poised to make a significant impact on the welding market and become a preferred choice for professionals seeking superior welding equipment.In conclusion, the launch of the IGBT Inverter Welder by {Company Name} introduces a new era of welding technology, offering welders a powerful and versatile tool that delivers exceptional performance and usability. With its advanced features, durability, and safety measures, this welding machine is poised to elevate the capabilities of welders and meet the demands of modern welding applications. For more information about the IGBT Inverter Welder and other products from {Company Name}, interested parties are encouraged to contact the company directly or visit its official website.

Top Welding Industrial Supply for Your Manufacturing Needs

Welding Industrial Supply has been a key player in the welding industry for the past 20 years, providing top-quality welding equipment, supplies, and services to a wide range of customers. This family-owned business has established a reputation for excellence and has been a trusted partner to businesses and individuals looking for reliable welding solutions.As a leading distributor of welding equipment and supplies, Welding Industrial Supply has always been committed to providing the best products and services to its customers. The company carries a comprehensive range of welding equipment, including welding machines, welding consumables, safety gear, and welding accessories. Their extensive inventory ensures that customers have access to the latest welding technologies and can find everything they need to complete their welding projects efficiently and effectively.Welding Industrial Supply has always been dedicated to meeting the diverse needs of its customers. Whether it's a small welding job or a large industrial project, the company has the expertise and resources to fulfill any welding requirement. They take pride in their ability to tailor their services to the specific needs of each customer, providing personalized solutions that deliver exceptional results.In addition to their extensive product range, Welding Industrial Supply also offers professional welding services, including equipment repair, maintenance, and calibration. Their team of experienced technicians has the skills and knowledge to handle all types of welding equipment, ensuring that it operates at peak performance and meets the highest safety standards. This commitment to service excellence has made Welding Industrial Supply a preferred partner for many businesses and organizations that rely on welding as a core part of their operations.Welding Industrial Supply has also been at the forefront of promoting welding safety and best practices. They understand the potential hazards associated with welding and have made it a priority to educate their customers on the importance of proper safety measures. The company offers a range of safety equipment and training programs to help businesses and individuals mitigate risks and create a safe working environment for their welding operations.Furthermore, as part of their ongoing commitment to environmental responsibility, Welding Industrial Supply has embraced sustainable practices in their operations. They have implemented environmentally friendly initiatives, such as recycling programs and energy-efficient solutions, to minimize their impact on the environment. By promoting sustainable welding practices, the company has positioned itself as a responsible and forward-thinking industry leader.Welding Industrial Supply's dedication to excellence, customer satisfaction, and innovation has earned them a solid reputation in the welding industry. The company has built strong, long-lasting relationships with its customers, and their commitment to quality and service has helped them stand out in a highly competitive market.Looking ahead, Welding Industrial Supply remains focused on expanding its product offerings, enhancing its service capabilities, and staying ahead of industry trends. With a clear vision for the future and a steadfast commitment to its core values, the company is well-positioned to continue serving as a trusted partner in welding solutions for many years to come.In summary, Welding Industrial Supply has established itself as a leading provider of welding equipment, supplies, and services, garnering a strong reputation for excellence, customer satisfaction, and innovation. With a comprehensive range of products, personalized service, a commitment to safety, and a focus on sustainability, the company has solidified its position as a trusted partner in the welding industry.

The Ultimate Guide to Dual Welders: Everything You Need to Know

Dual Welder Revolutionizes Welding Process{Company Name}, a leading manufacturer of welding equipment, has introduced a game-changing new product to make the welding process faster, more efficient, and safer. The Dual Welder, a cutting-edge welding machine, is set to revolutionize the way welding is done in various industries.The Dual Welder is a multi-process welding machine that allows operators to perform MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding with unmatched precision and control. This innovative machine is designed to increase productivity and reduce downtime, making it the ideal choice for both large-scale industrial applications and small-scale fabrication jobs.One of the key features of the Dual Welder is its ability to seamlessly switch between MIG and TIG welding processes without the need for manual adjustments or the use of separate equipment. This not only saves valuable time but also minimizes the risk of errors and inaccuracies, leading to superior welding results.In addition, the Dual Welder is equipped with advanced technology that ensures optimal weld quality, even in the most challenging welding scenarios. Its precise voltage and wire feed control, combined with its high-frequency start and lift arc technology, result in consistently high-quality welds on a wide range of materials, including steel, aluminum, and stainless steel.Safety is also a top priority with the Dual Welder. The machine is designed with built-in safety features, such as thermal overload protection and a voltage reduction device, to prevent overheating and electrical hazards. This provides operators with peace of mind while they focus on creating strong and reliable welds.Furthermore, the Dual Welder is built to withstand the rigors of industrial work environments. Its durable construction and reliable performance make it an indispensable tool for welders working in demanding conditions, such as construction sites, shipyards, and manufacturing plants."The introduction of the Dual Welder represents a significant leap forward in welding technology," said a spokesperson for {Company Name}. "We are proud to offer a product that not only enhances the efficiency and quality of welding operations but also prioritizes the safety of our customers. The Dual Welder is the result of our commitment to innovation and delivering solutions that exceed our customers' expectations."The Dual Welder has already garnered positive feedback from industry professionals who have had the opportunity to test the machine. Welders have reported significant improvements in their productivity and weld quality, as well as a notable reduction in the time required to switch between welding processes.As the manufacturing and construction industries continue to evolve, the Dual Welder is poised to play a vital role in meeting the growing demands for reliable and efficient welding equipment. Its versatility, precision, and safety features make it a valuable asset for businesses seeking to stay ahead in a competitive market.{Company Name} is dedicated to providing comprehensive support and training for customers who choose to integrate the Dual Welder into their operations. They offer a range of resources, including on-site demonstrations, instructional materials, and technical assistance, to ensure that customers can maximize the benefits of this cutting-edge welding machine.In conclusion, the introduction of the Dual Welder represents a significant advancement in welding technology that promises to revolutionize the welding process. With its ability to seamlessly switch between MIG and TIG welding processes, its advanced technology, and its focus on safety and durability, the Dual Welder sets a new standard for welding equipment. As industries continue to evolve and demand more efficient and reliable welding solutions, the Dual Welder is poised to meet and exceed these demands, making it an indispensable tool for welders across various sectors.